Yamaha Robotics EMEA

Trusted Solutions for Surface-Mount Electronics Assembly and Factory Automation

Yamaha Robotics Division, through its Factory Automation Section (FA Section) and Surface-Mount Technology Section (SMT Section), empowers manufacturing and logistics businesses to raise output and productivity using advanced automation.

Surface Mount Technology (SMT)

The SMT Section delivers advanced solutions for electronic manufacturing businesses, based on state-of-the-art inline automation. The product portfolio addresses all aspects of populating printed circuit boards, from stencil printing and dispensing electronic materials such as solder paste and adhesives, through 3D solder paste inspection (SPI), high-speed component placement, and 3D automatic optical inspection (AOI), as well as intelligent, connected component storage. There are also high-accuracy hybrid bare-die/SMD-chip placement platforms, perfect for assembling electronic modules including MEMS sensors and power controllers as well as semiconductor back-end processes such as flip-chip packaging.

read moreDrawing on hardware and software intellectual property built up over many product generations, and the expertise of its engineering staff to deliver creative solutions, these platforms handle the complexity of today’s electronic assembly challenges and ensure outstanding repeatability and end-of-line yield; ultimately ensuring commercial success for manufacturers by delivering total satisfaction for their customers. With a flexible range of product choices, the SMT Section offers a 1 Stop Smart Solution for data-driven manufacturing, that gives customers the flexibility to optimise and scale their production capacity and capabilities.

Factory Automation (FA)

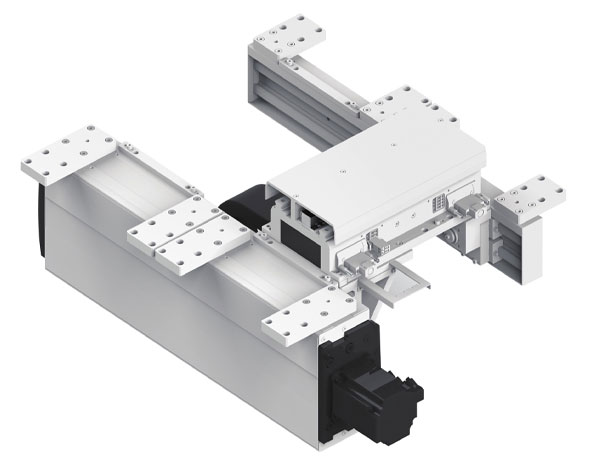

The FA Section has evolved from a group formed within Yamaha to automate aspects of motorcycle manufacturing using flexible, precision robots. Today, FA Section offers SCARA and cartesian robots, linear transfer modules, and vision systems that are used in industries from microelectronics to consumer products, food production, aerospace, automotive, and more, and trusted by customers ranging from small enterprises to blue-chip corporations. Configured for standalone use, or connected in infinitely flexible ways to perform almost any sequence of processes, they can address a wide variety of parts-handling and light mechanical assembly tasks involving payloads up to about 50kg.

read moreTo efficiently move workpieces between robots working together, the LCMR200 linear conveyor module is unique to Yamaha and provides bidirectional transport with programmable speed and start/stop positions. It can also provide flexible transport between workstations of a conventional production line.

An extensive selection of controllers is available that allow interacting with their robots using popular industrial Ethernet and fieldbus protocols, including PROFINET, EtherNet/IP, EtherCAT, PROFIBUS, CC-Link, DeviceNet, and EtherNet/IP. There are also accessories and options to maximise performance, including the RCXiVY2+ vision system with optional high-speed tracking and new blob detection for handling irregular-shaped objects, a selection of electric grippers, and the RCX Studio GUI with its new 3D simulator for rapid setup and programming.

Head of management

Welcome to Yamaha Robotics

We aspire to create innovative products that deliver unique value to our customers.

Our business unit offers a portfolio that contains industry-award winning equipment for electronic surface-mount manufacturing and our growing selection of high-speed industrial robots for precision assembly, handling, and packaging. Furthermore, we continue to innovate as we infuse state-of-the-art technologies like artificial intelligence and data analytics into our platforms.

Both teams from Surface Mount Technology and Factory Automation sections in Europe are dedicated to supporting our customers from diverse industrial sectors with advanced solutions. At Yamaha Robotics, we are committed to continuously create reliable technologies to best serve our customers.

Ai Nagakubo

Branch Manager

Corporate philosophy

The spirit of challenge is within Yamaha Robotics Business founding philosophy.

Over 35 years, Yamaha’s expertise and collective power aim to deliver ingenuity and passion in Yamaha’s SMT & SPI parts that provide excep-tional value and deep satisfaction. All Yamaha’s innovations in advanced technologies are driven to create connection with customers and respond to their evolving needs.

Yamaha Robotics Business is dedicated to achieve success by always exceeding customer expecta-tions with reliable, high-quality products and services. Yamaha, Trusted Technology, incorpo-rates values inspired by the spirit of Kando, emotional involvement and power to create, and is committed to best serve its customers and partners.

Latest news releases

Yamaha to showcase latest-generation assembly equipment and software tools at SMTconnect

Apr 15, 2024 | SMT News Release

Yamaha Robotics SMT Section will team with its distributor ANS Elektronik to showcase innovations for high-speed surface mount assembly at SMTconnect 2024.

Scaling Manufacturing Output with Flexible Factory Automation

Mar 11, 2024 | FA News Release

Typical factory automation systems are fast and accurate, by design. Scaling the system to increase production, on the other hand, can be a challenge.

How to Work with the Intelligent Factory

Mar 04, 2024 | SMT News Release

The intelligent factory works with production teams, through powerful software tools, to raise productivity by improving production plans, minimising stoppages, and accelerating troubleshooting.